Have you ever dreamed of making your own luxurious, Castile soap? In this blog post, you'll learn how to make Castile soap with pure 100% olive oil while demystifying the process with our step-by-step guide.

Olive oil, renowned for its skin-loving properties, takes center stage in this timeless recipe, ensuring a luxuriously cleansing experience. This classic soap is perfect if you're looking for a pure, natural soap experience.

What Is Castile Soap?

Castile soap, named after the Castile region of Spain, is a simple yet versatile soap made purely from olive oil. Traditionally crafted using a cold process method, it's a popular choice for those seeking natural and vegan-friendly alternatives.

Pure olive oil soap bars boast a unique set of benefits. Their gentle cleansing properties, derived from olive oil's natural emollients, are kind to even sensitive skin.

The cured bars produce a rich, creamy lather that cleanses without stripping away the body's natural barrier, leaving the skin feeling soft and nourished.

Jump to:

- What Is Castile Soap?

- What Makes Castile Soap Different?

- What You'll Need To Make Pure Olive Oil Soap

- Step-by-Step Guide How To Make Castile Soap

- Unmold And Cure The Bars

- Storing Cold Process Soap

- Troubleshooting Cold Process Castile Soap

- Basic Cold Process Soap Making Equipment

- Safe Lye Handling Tips

- More Fun Projects To Explore

What Makes Castile Soap Different?

Olive oil is primarily composed of monounsaturated fatty acids, with Oleic acid being the most prominent, typically ranging from 70% to 85% of the total fatty acid content. This fatty acid is slow reacting to sodium hydroxide solutions.

This causes Castile soap to saponify and cure very slowly. You'll want to use a mold you won't need for up to 2 weeks, as the soap log can be very soft when handling. Additionally, once you've sliced your soap, it will need to cure and age for up to 1 year to fully mature and develop good lather.

While safe to use after 3 to 4 days, the lather on a ‘young’ uncured bar of Castile soap is skimpy and slimy. If you let your Castile soap bars age (just like wine or cheese!), they will cure and transform into rock solid hard bars (be careful not to drop it on your foot!). The stingy, slimy lather blooms into a much more robust, lather of creamy bubbles.

What You'll Need To Make Pure Olive Oil Soap

For true Castile soap you'll only need three ingredients: Olive oil, water, and sodium hydroxide. It's very common to add a light touch of lavender essential oil though, but not required.

This soap recipe comfortably fits a 42 to 48 oz log mold, and makes about 10 - 12 bars of Castile soap (depending on size you cut your bars).

- Olive oil - Any variety, but extra virgin olive makes pale green soap, and golden olive oil maker a whiter soap.

- Water - Distilled, or tap, either are fine.

- Sodium hydroxide (lye).

- Lavender essential oil, Optional. Castile is commonly unscented, or lightly scented with lavender essential oil.

See the project printable for exact measurements and expanded directions.

Choose Which Olive Oil To Use

There are several grades of olive oil to choose from, and you can use any of them to make Castile soap.

Choose from extra virgin olive oil, golden olive oil, and pomace olive oil. The differences are the purity of the olive oil, with extra virgin being the first press, golden olive oil coming from subsequent presses, and pomace olive oil from the final pressing from the pulp and olive seeds.

For the lightest colored soap, use golden olive. Extra virgin and virgin olive oil traces the slowest and you'll have pale green soap. Pomace traces the fastest, but it not as readily available. Pomace will also make an off color soap.

Step-by-Step Guide How To Make Castile Soap

Patience is the key with Castile, both in ageing it to a fine bar of soap to use, but also in the preparation and mixing of the batch.

Castile Soap is so high in Oleic and Linoleic acids that this batch of soap takes forever to come to even a light trace. To enhance saponification, we are going to use a lye solution about 100 degrees F, and heat our olive oil up to 110 - 120 degrees F.

We will also reduce the water to a 37% discount. By using less water we concentrate the lye solution, which in turn speeds up the saponification. It can reduce curing time a little also. I have a full tutorial on DWCP (Discounted Water Cold Process) if you'd like to learn more about it.

Make sure you have all your safety equipment on hand. Googles, apron, gloves. Have your stick blender, lined mold or silicone mold already prepared and waiting.

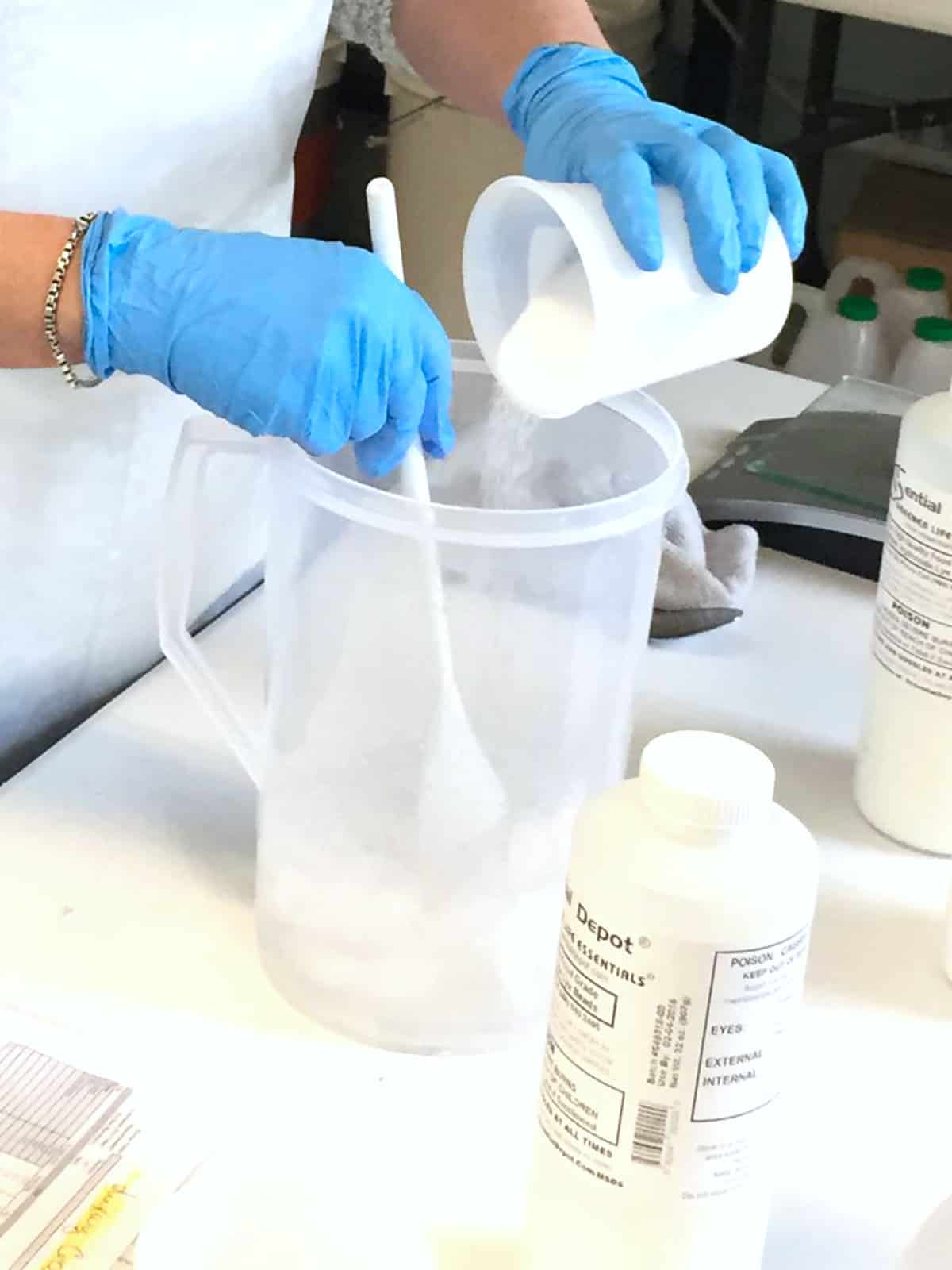

Prepare The Lye Solution

Making soap involves handling lye, which can be dangerous if not handled properly. Please ensure you research safety precautions thoroughly before attempting this project.

- Weigh your water in a safe, plastic pitcher. You can use distilled water, or simply cold tap water. Set to the side.

- Weigh the sodium hydroxide, and carefully add it to the pitcher of water, stirring until dissolved. It will look milky, or cloudy. Set aside and wait until it is no longer cloudy, and cooled to about 110 - 115 degrees F.

Measure And Warm The Olive Oil

- Place your stockpot on a scale and tare it to zero. Add your olive oil to the measurement shown in the How To card.

- Remove the stockpot from the scale and heat on the stovetop until it reaches between 110 and 120 degrees F. This starting heat will give the olive oil molecules a ‘boost’ and get us to a medium trace sooner, without burning out the motor on the stick blender.

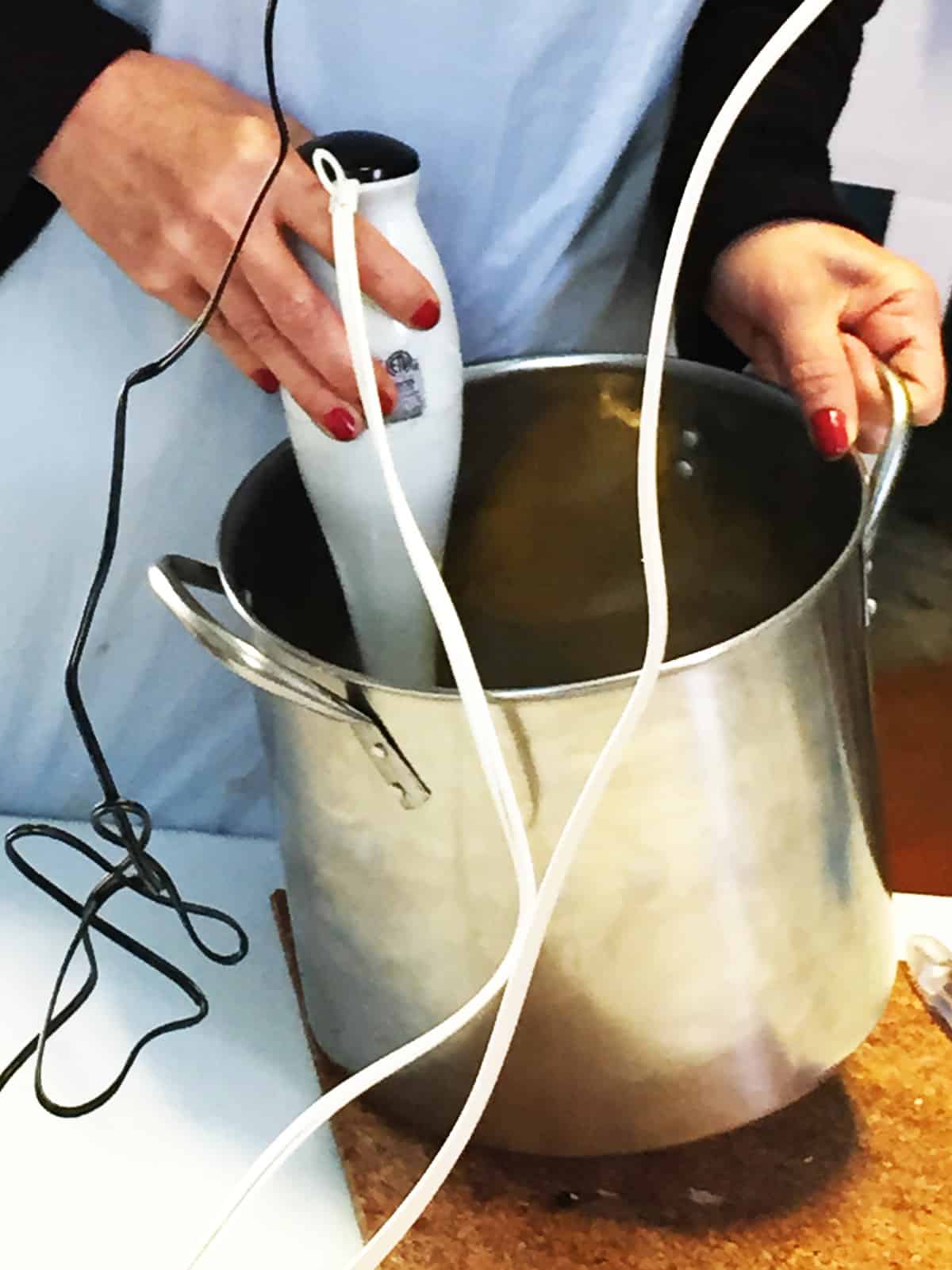

Bring Soap Mixture To Trace

- Slowly pour your hot lye solution in a thin stream into your hot olive oil. Stir slowly with a spoon while you pour until all the lye solution has been emptied into your oils.

- Stir with your spoon until the mixture is cloudy and holding together, then start using your stick blender on low.

- If adding lavender essential oil, do so now.

- Gently stick blend and bring your soap to a light to medium trace. Trace is when the oils and lye solution have emulsified and thickened. Ideally, you'd like your Castile soap mixture to have the consistency of pancake batter, where it coats a spatula and stays on it. If you get a higher trace that's even thicker, that is great as it lets you create “peaks” with the top of your soap after you pour it into a mold.

Pour Traced Soap Mixture Into The Mold

- Once you are at a light to medium trace, you can pour your soap into a single mold or into individual molds.

- Tap the mold on your work surface to eliminate any air pockets or bubbles.

Unmold And Cure The Bars

- Let your soap sit covered with a mold cover or a towel to set up. It will most likely go through a gel phase. Do not try to take it out of the mold for at least 3 days though, as it will be too soft to handle before this. It is normal to have to wait up to 2 weeks to remove from the mold, depending on the variety of olive oil you used. This is normal.

- Once your soap can be easily handled, remove from the mold. For logs, slice into bars immediately.

- Place the bars of soap in a location that has some free flowing air, is not moist, and can remain undisturbed for several months. On top of a book shelf, spare closet, or even a shelf in your laundry room or garage.

- Check your soap bars every month, turning them. Cure for one year for fully cured 100% olive oil Castile soap. The lather will have much more bubble, and you won't get that slimy skin that immature Castile soap creates.

Storing Cold Process Soap

Once the long curing process is complete, you can wrap, store, and use your cured pure Castile soap just like you would any other type of cold process soap.

- Wrap your fully cured bars in wax paper, tissue paper, or any other packaging you like.

- Store your cured soap bars in a cool dry cupboard or closet that you keep other personal care products for a long shelf life.

- You can store your soap in small plastic storage bins as well.

Troubleshooting Cold Process Castile Soap

The Castile soap-making process is not really tricky, just a test of patience. Don't be surprised if it seems like forever to come to trace, forever to be able to remove from the mold, and forever for your cut bars to become hard bars. This is just the nature of pure, 100% olive oil soap.

- Keep your lye solution and olive oil no hotter than the 110 degrees F range, as too hot can contribute to volcano overflow in some molds (deep, wood insulated).

- Use a light hand with the addition of the lavender essential oil if you include it. It can regress trace even more! You just want enough to add a hint of lavender, about ½ oz per pound of oil.

- Let the soap sit in the mold as long as it needs to become firm and easy to unmold. This can take up to 2 weeks depending on the grade of olive oil you chose. Extra Virgin Olive oil will be the slowest to firm up.

- For soap that sets up a little faster, dissolve 1 teaspoon of salt to 1 tablespoon of water. Add after you first mix in the lye solution.

- If you decide to make a smaller batch, be sure to use a lye calculator to properly calculate your oil, lye, and water.

Basic Cold Process Soap Making Equipment

This list of equipment and supplies is not comprehensive, but it covers the basics to make this cold process soap recipe easily. You can confiscate items from your kitchen, but be sure to wash them well if returning them afterwards.

As an Amazon Associate I earn from qualifying purchases.

- Scale

- Stock Pot - 8 quart

- Silicone Spatula

- Nitrile Gloves

- Goggles

- Face Shield

- Chemical Resistant Apron

- Stick Blender

- Thermometer

- 42 oz log mold, silicone lined

- 48 oz log mold, silicone lined

- Freezer paper

Safe Lye Handling Tips

- Always wear gloves and either a face face mask or goggles when making soap. An apron and long sleeves is recommended also.

- Keep long hair tied back, out of the way.

- Always pour the measured lye crystals or beads into the cold water.

- Prepare your lye solutions in a well-ventilated area.

- Keep pets and children out of the area.

- In the event of a lye spill, sop up with towels and rinse in cold water.

- In the event that you get lye solution on your skin or eyes, FLUSH WITH COLD WATER. Don't ever use vinegar to neutralize a lye solution on the skin. All SDS documents clearly state flushing with water is the first course of first aid, as it dilutes the alkalinity without a chemical reaction.

More Fun Projects To Explore

Pure Olive Oil Castile Soap Recipe

Equipment

- Scale

- Stock Pot - 8 quart

- Silicone Spatula

- Nitrile Gloves

- Goggles

- Face Shield

- Chemical Resistant Apron

- Stick Blender

- Thermometer

- 42 oz log mold, silicon lined

- 48 oz log mold, silicon lined

- Freezer paper

Ingredients

- 7.0 oz Water distilled water or tap water

- 4.1 oz Sodium hydroxide dry, beads or crystals

- 32 oz Olive Oil extra virgin, pomace, or golden

- 1½ oz Lavender essential oil Optional

Instructions

Prepare The Lye Solution

- Weigh your water in a safe, plastic pitcher. Set to the side.7.0 oz Water

- Weigh the sodium hydroxide, and carefully add it to the pitcher of water, stirring until dissolved. It will look milky, or cloudy. Set aside and wait until it is no longer cloudy, and cooled to about 110 - 115 degrees F.4.1 oz Sodium hydroxide

Measure and Heat the Olive oil

- Place your stockpot on a scale and tare it to zero. Measure the olive oil directly into the tared stockpot on the scale.32 oz Olive Oil

- Remove the stockpot from the scale and heat on the stovetop until it reaches between 110 and 120 degrees F. This starting heat will give the olive oil molecules a ‘boost’ and get us to a medium trace sooner, without burning out the motor on the stick blender.

Stick Blend and Bring to Trace

- Slowly pour your lye solution in a thin stream into your warmed olive oil. Stir slowly with a spoon while you pour until all the lye solution has been emptied into your oils.

- Stir with your spoon until the mixture is cloudy and holding together, then start using your stick blender on low.

- If adding lavender essential oil, do so now.1½ oz Lavender essential oil

- Gently stick blend and bring your soap mixture to a light - medium trace. Trace is when the oils and lye solution have emulsified and thickened. Ideally, you'd like your Castile soap mixture to have the consistency of pancake batter, where it coats a spatula. If you get a thicker trace that's even better, as it lets you create “peaks", or texture after you pour it into a log mold.

Pour Traced Soap Into A Mold

- Once you are at a light to medium trace, you can pour your soap into a single mold or into individual molds.

- Tap the filled mold on your work surface a few times to eliminate any air pockets or bubbles.

Unmold and Cure The Bars

- Let your soap sit covered with a mold cover or a towel to set up. It will most likely go through a gel phase. Do not try to take it out of the mold for at least 3 days though, as it will be too soft to handle before this. It is normal to have to wait up to 2 weeks to remove from the mold, depending on the variety of olive oil you used. This is normal.

- Once your soap can be easily handled, remove from the mold. For logs, slice into bars immediately.

- Place the bars of soap in a location that has some free flowing air, is not moist, and can remain undisturbed for several months. On top of a book shelf, spare closet, or even a shelf in your laundry room or garage.

- Check your soap bars every month, turning them. Cure for one year for fully cured 100% olive oil Castile soap. The lather will have much more bubble, and you won't get that slimy skin that immature Castile soap creates.

Notes

- Making soap involves handling lye, which can be dangerous if not handled properly. Please ensure you research safety precautions thoroughly before attempting this project.

- Keep your lye solution and olive oil no hotter than the 110 - 120 degrees F range, as too hot can contribute to volcano overflow in some molds (deep, wood insulated).

- Use a light hand with the addition of the lavender essential oil if you include it. It can regress trace even more! You just want enough to add a hint of lavender, about ½ oz per pound of oil.

- Let the soap sit in the mold as long as it needs to become firm and easy to unmold. This can take up to 2 weeks depending on the grade of olive oil you chose. Extra Virgin Olive oil will be the slowest to firm up.

- For soap that sets up a little faster, dissolve 1 teaspoon of salt to 1 tablespoon of water. Add after you first mix in the lye solution.

Leave a Reply